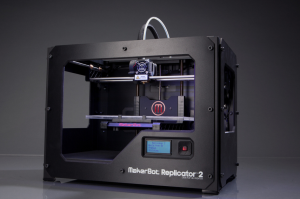

*Photo taken from Flickr w/Attribution CC License: http://bit.ly/1UnoxIN

Many institutions have seen the rise of makerspaces within their libraries, but it’s still difficult to get a sense of how embedded they truly are within the academic fabric of their campuses and how they contribute to student learning. Libraries have undergone significant changes in the last five years, shifting from repositories to learning spaces, from places to experiences. It is within these new directions that the makerspace movement has risen to the forefront and begun to pave the way for truly transformative thinking and doing. Educause defines a makerspace as “a physical location where people gather to share resources and knowledge, work on projects, network, and build” (ELI 2013). These types of spaces are being embraced by the arts as well as the sciences and are quickly being adopted by the academic community because “much of the value of a makerspace lies in its informal character and its appeal to the spirit of invention” as students take control of their own learning (ELI 2013).

Nowhere is this spirit more alive than in entrepreneurship where creativity and innovation are the norm. The Oklahoma State University Library recently established a formal partnership with the School of Entrepreneurship to embed 3D printing into two pilot sections of its EEE 3023 course with the idea that if successful, all sections of this course would include a making component that could involve more advanced equipment down the road. Students in this class work in teams to develop an original product from idea, to design, to marketing. The library provides training on coordination of the design process, use of the equipment, and technical assistance for each team. In addition, this partnership includes outreach activities such as featuring the printers at entrepreneurship career fairs, startup weekends and poster pitch sessions. We have not yet started working with the classes, so much of this will likely change as we learn from our mistakes and apply what worked well to future iterations of this project.

This is all well and good, but how did we arrive at this stage of the process? The library first approached the School of Entrepreneurship with an idea for collaboration, but as we discovered, simply saying we wanted to partner would not be enough. We didn’t have a clear idea in mind, and the discussions ended without a concrete action plan. Fast forward to the summer, when the library was approached and asked about something that had been mentioned in the meeting-a makerspace. Were we interested in splitting the cost and pilot a project with a course? The answer was a resounding yes.

We quickly met several times to discuss exactly what we meant by “makerspace”, and we decided that 3D printing would be a good place to start. We drafted an outline that consisted of the equipment needed, which consisted of three Makerbot Replicator 5th generation printers and one larger Z18 along with the accompanying accessories and warranties. This information was gathered based on the collective experiences of the group along, with a few quick website searches to establish what other institutions were doing.

Next, we turned our attention to discussing the curriculum. While creating learning outcomes for making is certainly part of the equation, we had a very short time frame to get this done, so we opted for two sets of workshops for students with homework in between culminating in a certification to enable them to work on their product. The first workshop will walk them through using Blender to create an original design at a basic level, the second is designed to have them try out the printers themselves. In between workshops, they will watch videos and have access to a book to help them learn as they go. The certification at the end will consist of each team coming in and printing something (small) on their own after which they will be cleared to work on their own products. Drop-in assistance as well as consultation assistance will also be available, and we are determining the best way to queue requests as they come in knowing that we might have jobs printing over night, while others may come in at the very last minute.

Although as mentioned, we have just started on this project, we’ve learned several valuable lessons already that are worth sharing-they may sound obvious, but are still important to highlight:

- Be flexible! Nothing spells disaster like a rigid plan that cannot be changed at the last minute. We wanted a website for the project, we didn’t have time to create one. We had to wait until we received the printers to train ourselves on how they worked so that we can turn around and train the students. We are adapting as we go!

- Start small. Even two sections are proving to be a challenge with 40+ students all descending on a small space with limited printers. We hope they won’t come to blows, but we may have to play referee as much as consultant. There are well over 30 sections of this course that will present a much bigger challenge should we decide to incorporate this model into all of them.

- Have a plan in place, even if you end up changing it. We are now realizing that there are three main components to this collaboration all of which need a point person and support structure: tech support, curriculum, and outreach. There are 4 separate departments in the library (Research and Learning Services, Access Services, Communications, and IT) who are working together to make this a successful experience for all involved, not to mention our external partners.

Oh yes, and there’s the nagging thought at the end of each day-please, please, let this work. Fingers crossed!